Smart design, sturdy quality!

Undercarriage, upper structure, cab, arm, bucket – at first glance, all excavators look the same. However, a closer inspection reveals the many advanced ideas that make a Takeuchi stand out from the competition. ‘Smart design, sturdy quality!’ is our motto for all the innovations that enhance the efficiency of our construction machines and make life easier for their operators without compromising on excavator reliability.

Simply click the hotspots to obtain detailed information about the superior technical features that make Takeuchi construction machines special and see the models for which they are available.

1 Hydraulic quick hitch

Tools boost the efficiency of construction machines. With our hydraulic quick hitch (operated via the 3rd control circuit; as standard in configuration variant V2 and higher), tool changes can be effected from the cab by simply pressing a button – for speed, convenience and a precision fit. Doubling up on safety: all quick-hitch supply lines are installed on the bucket arm in a tear-safe manner and accidental opening of the quick hitch is prevented by a safe lock.

Available (from configuration V2) for the following models

2 A genuine all-rounder – The PowerTilt

With an operating range of up to 180°, the original Powertilt offers optimum manoeuvrability and highly flexible work in three dimensions. Functioning just like a human wrist, it saves time by reducing unnecessary travel motions and raises productivity. The joysticks can conveniently tilt the Powertilt in any position desired. Here too, all Powertilt supply lines are naturally installed on the bucket arm in a tear-safe manner.

Available (from configuration V3) for the following models

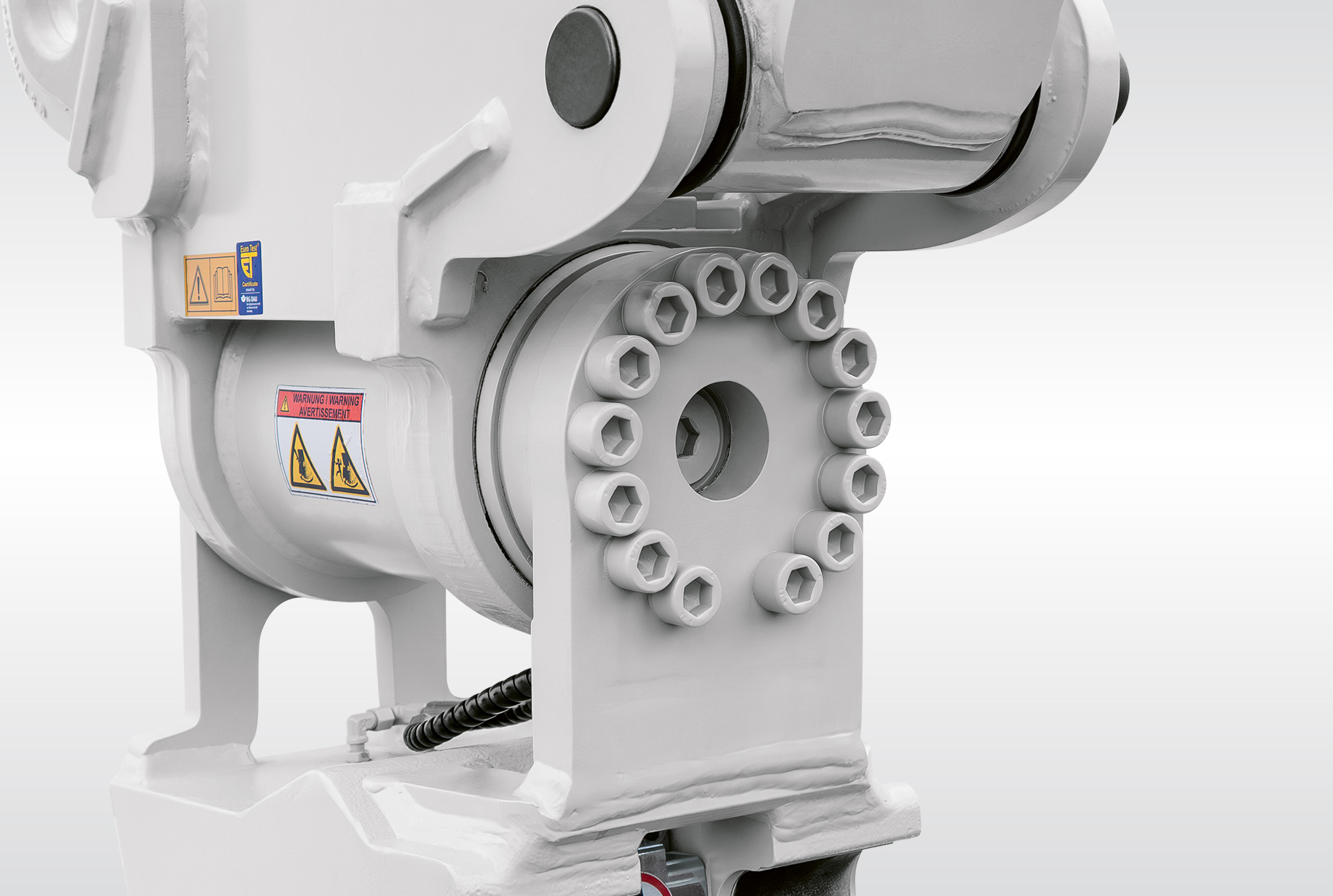

3 Fast and accurate – The TAKLOCK quick-hitch system

Simply insert the coupling block into the TAKLOCK quick-hitch system and push the locking lever up. Done! Connecting pressurised attachments has never been faster or more accurate. The TAKLOCK comes with two connections, one of which is reserved for the Powertilt and the other for the hydraulic attachment. A must for every equipment owner or operator working with hydraulic attachments, the TAKLOCK has an ultra-flat design which protects it from dirt and damage at all times.

Optional (from configuration V2) for the following models

4 Four in a row – Auxiliary circuits

All Takeuchi excavators in weight class 1.6 t and higher come with four auxiliary circuits boasting tear-safe installation from drawbar to bucket as standard. This takes the scope of possible applications and efficiency to a new level. The control circuits are individually programmable and support proportional control. Auxiliary circuits 1, 2 and 4 enable the litre volume to be easily adjusted for the tool used. Control circuit 3 is reserved for the time-saving hydraulic quick hitch. And the pressure accumulator is used to depressurise the auxiliary circuits before changing the tools.

Optional (from configuration V2) for the following models

5 Spacious, convenient and comfortable – The cab

With the needs of operators in mind, Takeuchi builds cabs that offer maximum space, comfort and convenience. The wide doorways ensure easy access, while the large flat panes provide an uninterrupted 360° view. Adjustable air-cushioned seats and spacious footwells ensure stress-free working. Ergonomically arranged control elements, colour displays with machine functions and settings menus bring the finishing touches to the cab, featuring air-conditioning, USB connections, Bluetooth radio etc. depending on the model.

Available for the following models

6 Take a seat – Seat suspension system

Seats play a significant role in how excavator operators feel at the end of a day. This is why Takeuchi uses high-end Grammer seats. Models TB 225 and higher are equipped with seats offering an array of adjustment options and comfort features as standard – such as automatic weight adjustment, which sets the seat suspension for the operator’s weight. In addition, the entire seat can be moved forward and back and the headrest, arm- and backrest angle can be adjusted to fit each driver. Horizontal suspension provides additional comfort, and seat heating as standard ensures a comfortable ride even in winter.

Available for the following models

7 With touchscreen

The new operating concept with colour touchscreen and rotary push button was first installed in the TB 370 model. Functions that are frequently used, including worksite lighting and rear-view camera, are button-controlled while the air-conditioning system, DAB+ radio, Bluetooth and hands-free kit are operated via touchscreen. Litre volumes, pressure level and pressure-free return flow can be saved for easy access. The rotary push button can be used for setting the rpm and accessing the sub-menus.

Available for the following models

8 Noticeable improvement – Continuous duty mode

A little tool we installed in response to requests by excavator operators. Previously operators had to keep a button pressed at all times to maintain the supply of oil to the hydraulic attachment. In continuous duty mode, operators now need only press the button once and can then focus fully on operating or positioning their attachment (e.g. milling cutter or mowing bucket). An improvement which provides relief for thumbs – and their owners.

Available as standard for the following models

9 Convenient control from the cab – Hammer hydraulics

No need for operators to leave the cab to change the mode manually using tools. Hammer hydraulics come with an electric reverse valve for pressure-free return flow. This pressure-free return flow prevents the oil from flowing through the control block, instead directing it into the hydraulic tank. This prevents the oil from heating, minimises the return flow and thus allows the hydraulic attachment to function unimpaired.

Available as standard for the following models

10 Clean and clever – The exhaust system

Takeuchi opted for a clean and clever solution to prevent exhaust-gas pollution of environments such as façades or hedges. Instead of a low-mounted exhaust pipe like most construction machines, Takeuchi excavators come with a high-mounted exhaust pipe. Additional dispersion of the exhaust fumes prevents damage to façades or plants. As an additional benefit, trench workers near the machine are not directly exposed to exhaust fumes.

Available as standard for the following models

11 Ideal access – The bonnets

Regular servicing and maintenance are critical for machine reliability and longevity. Takeuchi always makes sure that all important components are easy to access. Bonnets come with gas pressure springs and can be opened widely for clear access to components of the engine and hydraulics systems as well as maintenance points. In addition, all Takeuchi bonnets are made from sheet steel, which increases durability as well as ruggedness and protects the components under the bonnet.

Available as standard for the following models

12 Safe and convenient – The refuelling pump

The refuelling pump and the filler neck can be accessed via a safe flap with separate lock. All excavators in weight classes of 3 t and over come with a refuelling pump with automatic shut-off as standard, preventing spilling or overflowing. Newer models such as the TB 370 even have an automatically retractable fuel hose. And the self-venting system facilitates a restart should you ever run out of fuel.

Available as standard for the following models

13 Tiltable cab

Maintenance and servicing of machines should always be as simple as possible. With this in mind, we have equipped some models with a tiltable cab. The tilting mechanism eliminates the need to remove steel covers and is supported by a gas pressure spring, enabling it to be operated by only one person. The mechanism ensures free access to the components of the hydraulic system installed under the cab, so that all necessary maintenance and servicing activities can be performed.

Available as standard for the following models

14 The gold standard in tight spots – The unique zero-swing excavator

As space is at a premium at many worksites, space-saving high-performance machines such as our zero-swing excavators are in high demand. The upper structure with arm and tail is designed to extend only a few centimetres beyond the machine’s undercarriage, so that these machines require even less space than reduced tail-swing excavators. Another clever solution is the offset-boom, with offset design enabling it to be moved back to the upper structure on the left or right. Shifting the centre of gravity allows forces to be absorbed close to the upper structure, further boosting the boom’s relatively high lifting capacity. Another advantage of the patented side-to-side boom system is that it offers a free view of the bucket at all times.

Available as standard for the following models

15 Available in two different designs – The dozer blade

Smartness squared: Takeuchi’s C-shaped dozer blades enable material to be moved forwards and sideways while preventing spillage in front of the track frame. The dozer blade length ensures high stability at all times during support and allows a good view of the dozer blade. Excavators TB 210 to TB 225 come with a variable-width dozer blade as standard. The dozer blade of models TB 230 to TB 2150 is suitable for highest loads, with attached blade, double-wall, torsion-resistant design and robust box section arms.

With long dozer blades and variable width as standard

Double-walled and torsion-resistant dozer blade as standard

16 3-flange track frame offering solid stability

Takeuchi uses only first-class track components, such as 3-flange rollers. Optimum contact between the track frame and the chain enhances the reliability of the chain track and improves tracking, particularly during rotation on hard soils. Our 3-flange track frames also cause significantly lower vibrations and wear, and therefore require significantly less servicing and maintenance.

Available as standard for the following models

17 Retractable track frame

Takeuchi excavators in weight classes 1.0 to 2.4 t come with a retractable track frame with continuous hydraulic expansion and thus variable width. Depending on the situation, this can increase stability during lateral work movements or work at inclined positions, and enables narrow or confined spaces to be passed safely. The telescopic cylinders come with piston-rod protection, while tear-safe installation of the hydraulic lines to the drive system prevents damage.

Available as standard for the following models